Hot stamping machines Foil-WEB RR 650, RR 850 and RR 1060

Highest flexibility thanks to a modular system – our Foil-WEB-Rotary machines

spmsteuer Foil-WEB – the rotary machines RR 650, RR 850 and RR 1060.

Suitable for paper, cardboard and the production of all kinds of packaging as well as security products with holograms. Designed with one or more finishing units.

Modular system

A decision for individual finishing modules (cassettes) and for highest flexibility. You configure the sequence of finishing processes inhouse, according to your job requirements and without the help of spmsteuer. Within only a few hours you combine various processes in one finishing machine such as:

- hot foil stamping

- hologram application

- cold foil transfer / UV-Casting

- blind embossing

- screen print

- a.s.o.

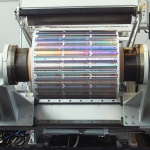

High Performance Foil Unit

Apart from the great precision in foil guidance, the newly designed foil unit has the following advantages:

- greatly reduced make-ready and down times

- further reductions in foil consumption

- good accessibility to all functions

- possibility of application of large foil roll diameters (up to 500 mm)

- number of foil webs for foil stamping: up to 16

- number of foil programs: 6

- continuous foil disposal (optional)

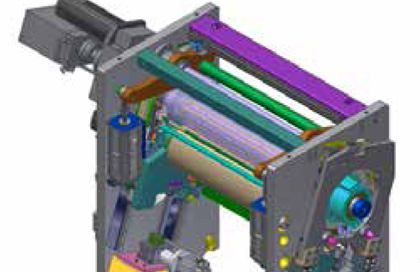

Patented sleeve Technology for Die and Impression Cylinder

Non-tool sleeve change within minutes (as opposed to costly cassette exchange). Sleeve technology advantages regarding job change:

- minimizing of make-ready time for size and motive changes

- cost reduction by well-priced sleeves

- standing froms for repeat jobs

The patented 4-point-bearer ring mounting means tolerance-free mounting of the stamping die cylinder.

Impression cylinder: Exchange sleeves for the impression cylinder make the use of various surface coatings possible, e. g. rubber or steel surfaces. Sleeves adapted to the diameter of the impression cylinder are used for application of male dies for blind embossing.

Heating: New infrared heating ensures short heating up period. Contactless temperature control guarantuees constant temperature. Higher temperatures (up to 300 °C) possibly allow higher speed.

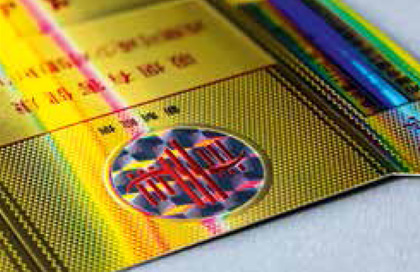

Hologram Control with Highest Precision

Every hologram mark is read individually, this means highest prescision. Application for:

- registered patches

- registered stripes

- registered transfer foil

Products:

- packaging of all kind such as cigarette packaging

- high security documents

- bank notes a.s.o.

Data:

- foil widths: 6 – 60 mm

- max. of 10 individually registered hologram webs

- production speed for holograms: 120 m/min.

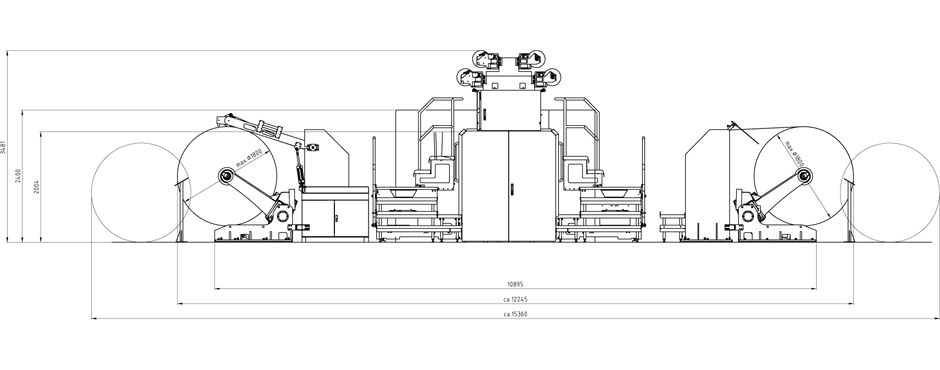

| Designation | Foil-WEB RR 650 / 850 / 1060 |

| Available web formats | 650 / 850 / 1,060 mm |

| Corresponding stamping formats | 630 / 850 / 1,040 mm |

| Repeat lengths | 565 – 1,256 mm |

| Working material | 40 – 500 g/m² |

| Max. web speed, mechanical | 200 m/min |

| Max. application speed for foil stamping | 150 m/min |

| Max. application speed for registered holograms | 120 m/min |

| Foil roll, diameter max. | 500 mm |

| Max. number of foil webs for foil stamping | 16 |

| Max. number of foil webs for registered holograms | 10 |

| Machine length | depending on configuration |

| Machine width | 5,450 mm |

| Machine height | 3,500 mm |